Traditional sourcing tools often get stuck with predefined cost sets, like shipping and processing fees. While these may seem convenient at first, they struggle to adapt to the ever-changing world of logistics and fulfillment. New carrier models and innovative local distribution strategies constantly emerge, introducing new cost structures that predefined sets can’t handle. For example, new local carrier models may have new or different costs the sourcing engine should consider like cost per stop vs. cost per package. A retailer may wish to define the holding cost of an item in addition to processing cost and the way these costs are assessed by 3PL’s may be different. As more innovative approaches to local distribution evolve you need an application that will grow with it. This further means that when new costs are required, there is typically a feature request or customization effort to add it.

In addition, these costs may or may not be on actuals. Because the cost in traditional approaches is simply a user input, while it is expressed in cost, it can be a proxy for a set of actual costs being tracked elsewhere. Our approach is to source the actual data so these costs represent real costs to the retailer. While proxy costs may seem easier to manage, having a data source representing real costs forces the discipline of the business to ensure these costs are accurate and have a business process to stay updated. Ultimately you want the decision making of your sourcing engine to be as close to what the accounting team is going to use when they produce monthly P&L. Where we see this typically breakdown is in carrier rates. Retailers will model a set of carrier costs based on two attributes like weight and zone. Meanwhile there is a more complex set of rate tables that governs the actual contract that includes dimensional weight, minimums, surcharges and accessorial costs.

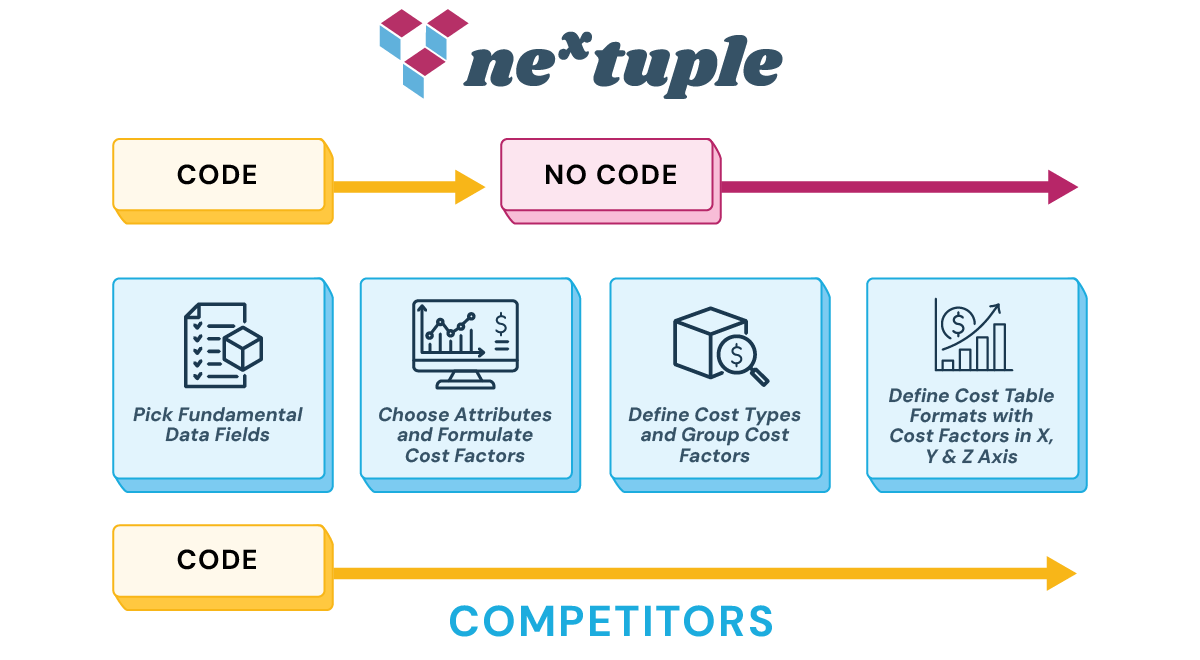

- Nextuple approaches cost definition in an entirely different way.

Costing always begins with data. While we offer multiple standard costs, all of these are enabled through a two-step process. The first step is acquisition of data fields that represent the costs. For example, for a given type of carrier service you may have four data fields such as item weight, zone of shipment, service level, and peak vs non-peak. Once these pieces of data are set up, how you define the costs are up to you. In our approach, this is the only development effort required. Once the data type is defined, it can used in any number of ways to define cost without development.

For example, the cost structure for item processing at nodes may be formulated on weight ranges and if the item is conveyable and if the store node has a full backroom operation. But let’s say you add in the capability to do gifting, and this becomes a new element in the processing cost formula. With our sourcing engine, the addition of data type “gift service” is the only thing you’ll need to code. How the cost is formulated with this new capability is handled through user configurations.